Surface Conditions

The better the surface condition, the more sensitive and reliable the test will be. Therefore, all contaminants such as paint, dirt, grease, oil, scale etc. are usually removed.

However, some MT techniques (e.g. yokes) can test through the layers of paint. Contrast paints should normally be in accordance with BS EN ISO 9934-2 Non-Destructive testing – Magnetic particle testing detection media. While other techniques such as Prods, which must have electrical contact with the test surface, must have the paint removed from the contact areas, as most paints are non-conductive.

Where dressing is not possible and when black inks are being used, a coating of a suitable white background contrast paint should be applied to improve resolution/sensitivity.

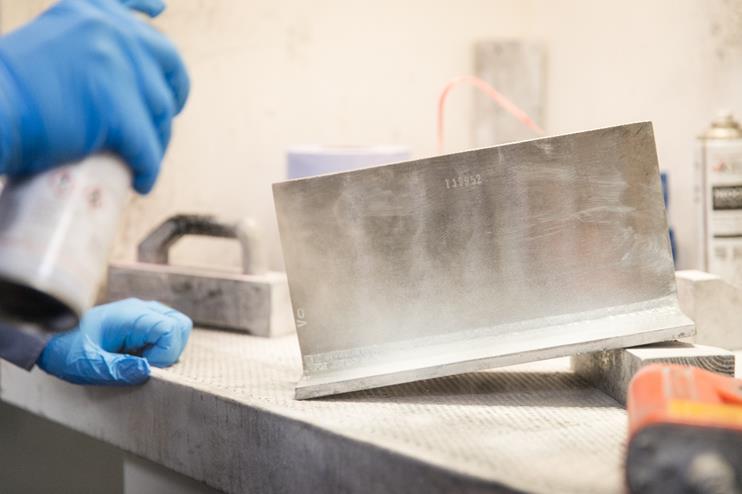

When testing machined parts with black ink, a contrast aid paint is not required due to the bright metal finish giving a good contrast.

Contrast paint should be applied as an even and thin layer. Thick coats reduce the sensitivity of the process and take longer to dry.

Contrast paints that are water based are not as toxic as those containing volatile solvents (aerosol cans) which may require increased ventilation or Personal Protection Equipment (PPE).